PS:One 15 Year Birthday Party – Saturday, April 13th

Join us on Saturday, April 13th @ 7pm for a night of fun, food, and music to celebrate 15

Join us on Saturday, April 13th @ 7pm for a night of fun, food, and music to celebrate 15

Hey all- Since we are not currently offering the-more-the-merrier office hours for authorizations, I have created this sheet to

To our members, The Mayor of Chicago has issued a stay at home advisory for the City of

What? :: Members create original designs. Members vote on the winner. The winning design gets printed on things (think

While we remain closed in compliance with the Illinois stay-at-home order, a small and dedicated team of volunteers has

We are fermenting up a tasty frothy storm over here in the PS1 kitchen! We have about 10 gallons

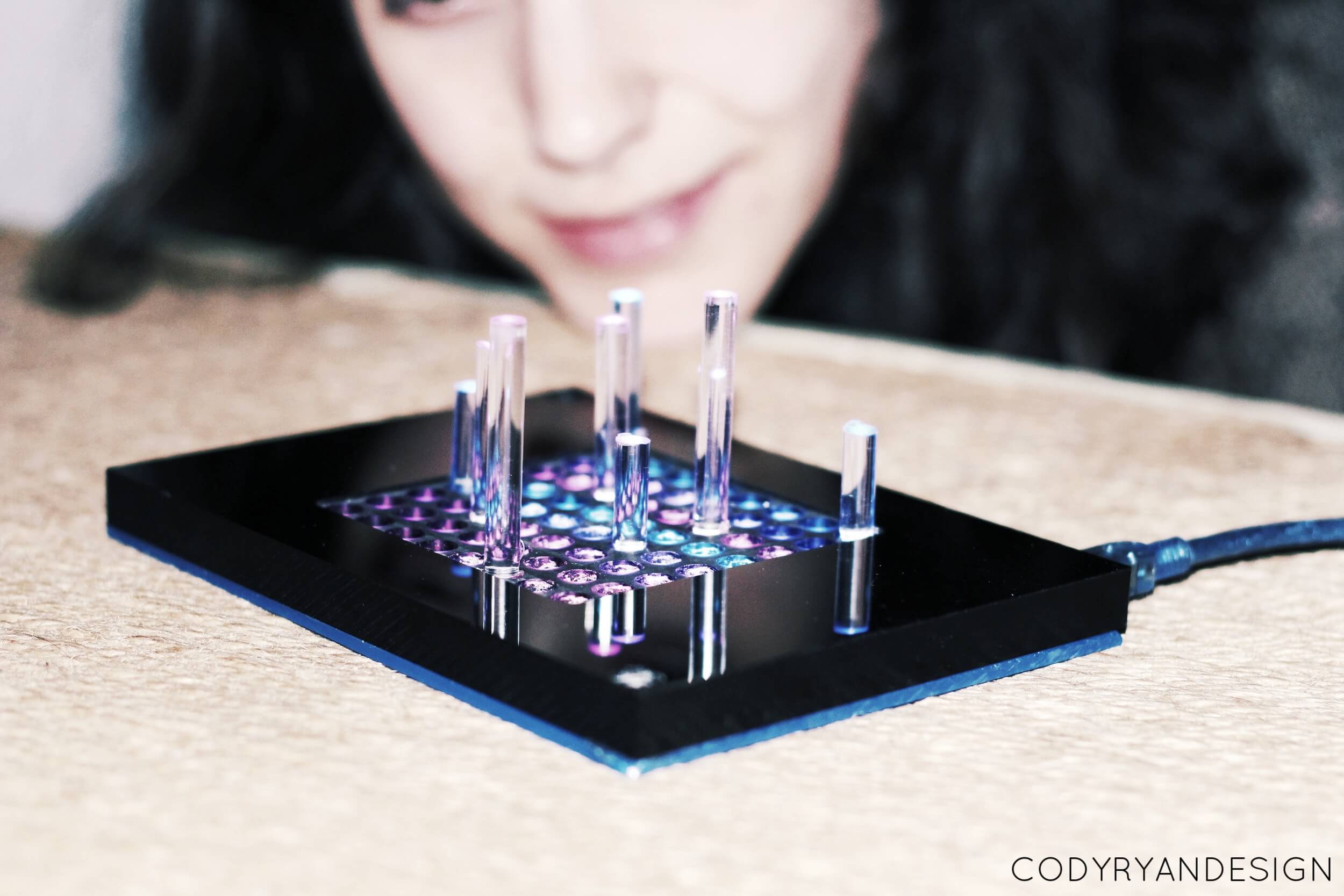

We’re excited to welcome CHI PRC’s Zine Zine Club Thursday 2/21 from 7-9pm in the lounge. We’ll be discussing DIY

Good news for Starving Hacker tier members: you can now vote at PS1 member meetings for things like purchases,

Site Design by Kevin Huemann