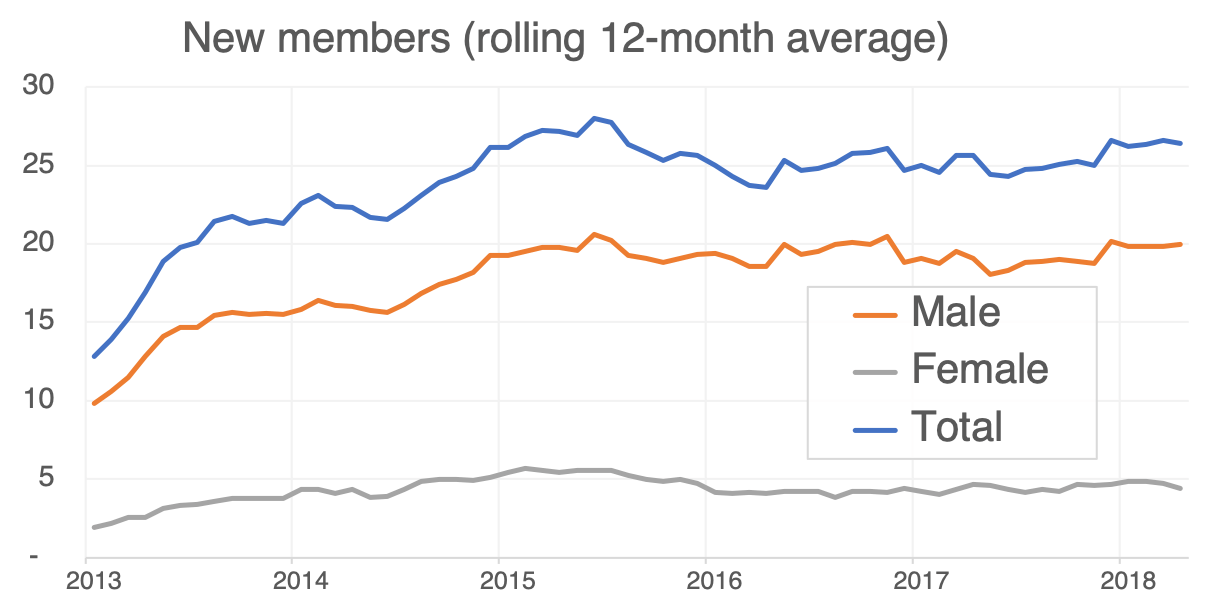

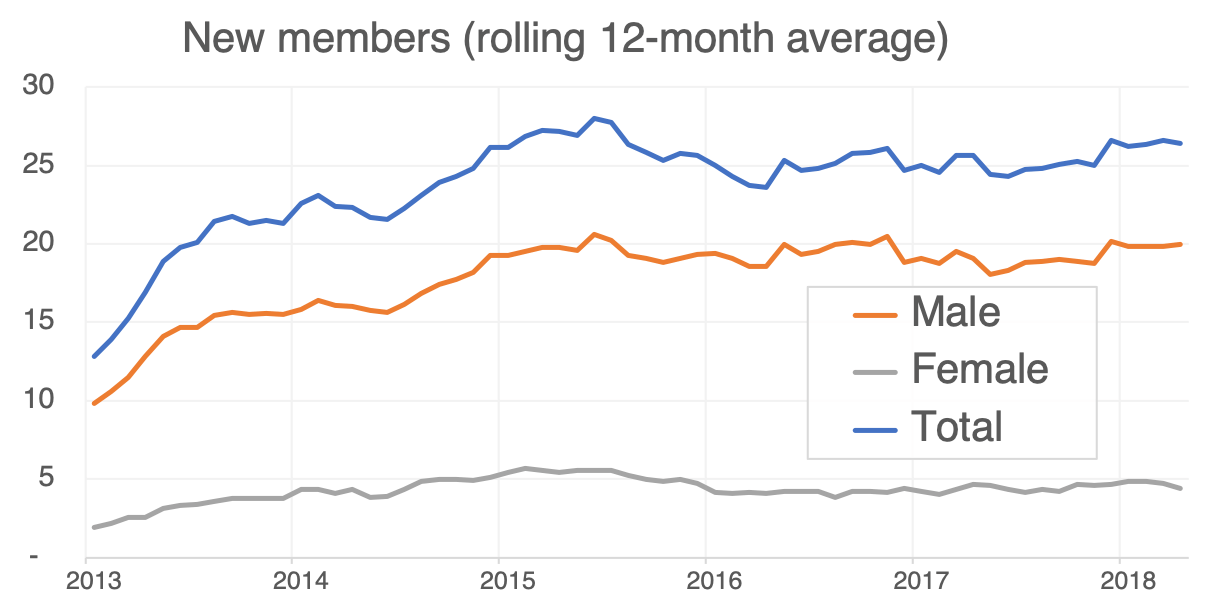

Growth and churn analysis of PS1’s membership

I used historical payment records to analyze member growth and member churn, the rates at which people join and

I used historical payment records to analyze member growth and member churn, the rates at which people join and

Update: great event! A recording is available here. All are encouraged to attend the candidate Q&A at PS1 on

In August, PS1 conducted its first-ever member survey to better find out who we are, how we use the

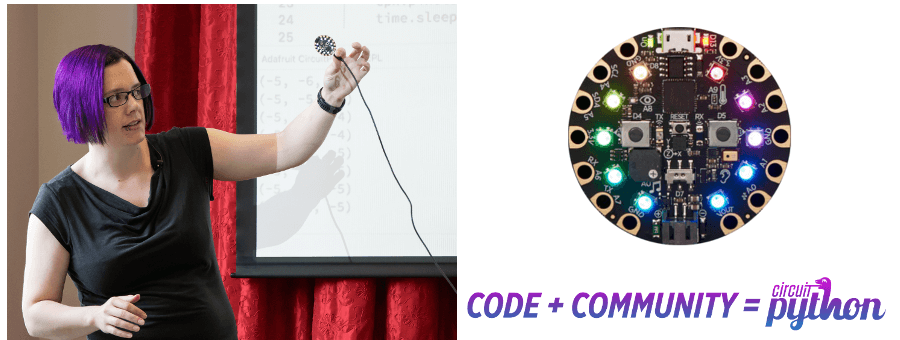

NERP (Not Exclusively Raspberry Pi) is PS1’s embedded programming interest group. At a special NERP on December 17, Kattni

PS1 will be holding annual board elections on January 15, 2019. Board elections affect everyone in the organization, whether

Update — that was pretty epic: Hebocon is a contest that pits tiny, crappy robots against one another in

Locktoberfest is coming back to PS1 on Sunday, October 14 from 11am to 5pm. The event is fun and

Open House Chicago is a great annual event. On the weekend of October 13 – 14, 250 locations across

Some important reminders: Please switch over the new member management system. We have streamlined the process further — see

Site Design by Kevin Huemann