As the old saying goes, it takes a village to replace Ash Jasani, and accordingly the responsibilities in the CNC area have now been distributed across three people. Thank you to three new area hosts for graciously offering their time:

- Andrew Sowa is host for the 3D printers

- Zander Bueno is host for the laser cutters (and vinyl cutter)

- Hank Peterson is host for machining — the ShopBot, Shapeoko, Tormach, and other devices for making chips

This change reflects a longstanding issue: the number of members and pieces of equipment has ballooned over the years, but the number of people filling operational roles has remained nearly constant. These means an ever-increasing workload for the area hosts, which in turn requires them to focus their energy on only the most pressing issues.

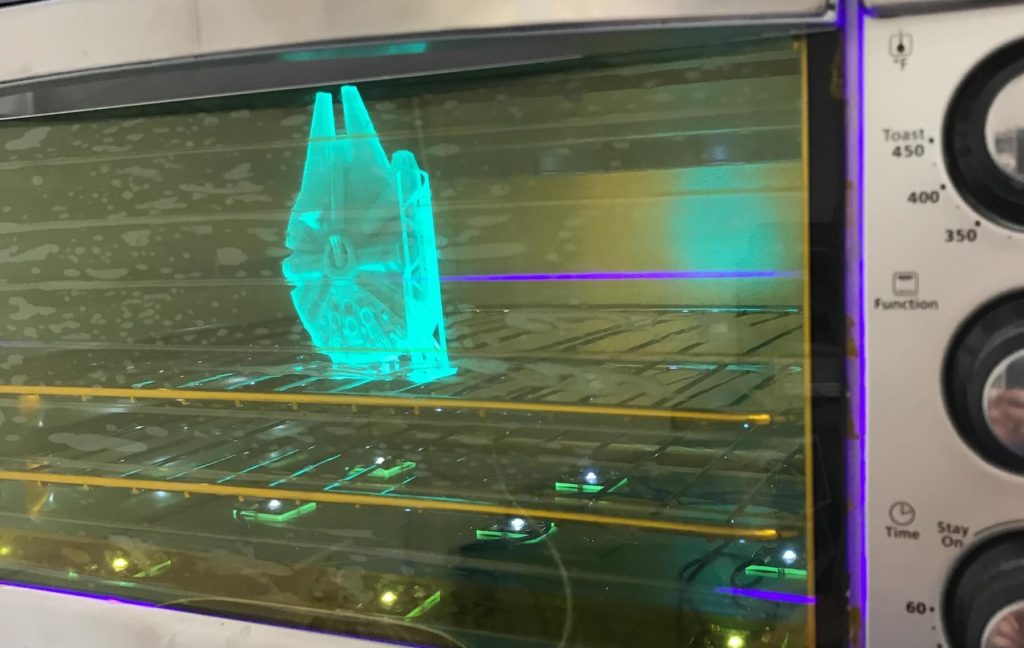

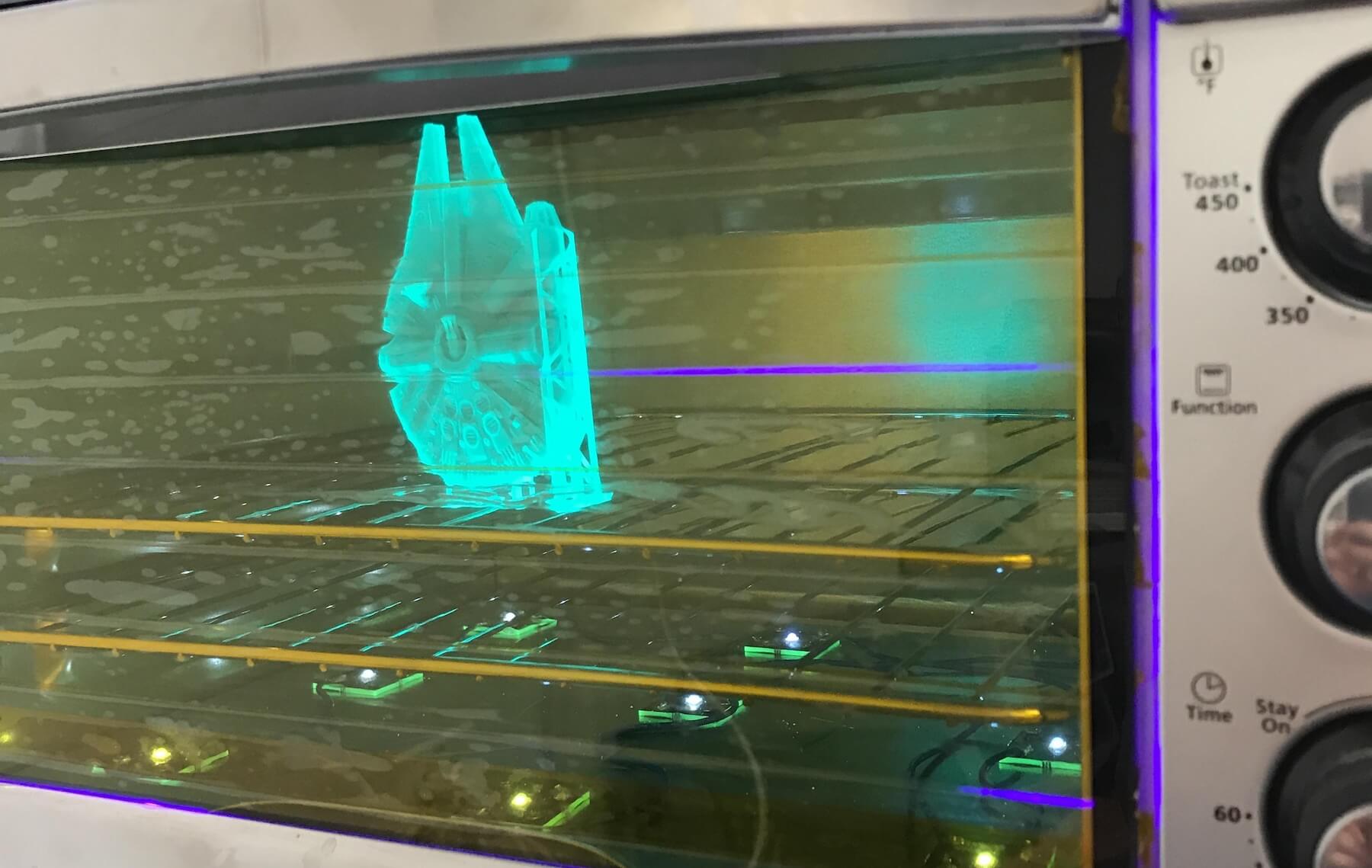

Dividing up responsibilities allows the hosts to focus their energy more narrowly and productively. As a case in point, Andrew Sowa has kicked off his tenure by donating a homemade post-cure station to PS:1.

This fancy Easy-Bake oven will make it easier to use our two Form 1 machines. Says Andrew:

UV resin does not come out of the printer fully cured, so further processing is required. UV light (405nm) and heat are applied to make sure the print is converted to a solid. This process can drastically change the material properties, and it is important that conditions be reasonably well controlled. My little toaster should offer good enough control of heat and light to dial in the best post-cure for different materials.

Also, it looks cool: